A Brief History of LED Grow Lights

To start off, this is just a brief history of LED grow lights. There is much more that could be shared about their history, but I really wanted to keep it as brief as possible.

There are many companies on the market selling grow lights and some definitely have some promising virtue. Kudos to the ones who help others come to a general understanding about the life-cycle of growing plants! Some companies do a poor job of putting technical information into layman’s terms so that the customer can understand it from their point of view. Customers aren’t always interested in the technical aspects of the lights. They sometimes just want to know if your product is of good quality and if it works, how it is going to benefit their plants, save them money and, if your guarantee satisfies their needs. We believe customer service is an outstanding aspect every business should have. We all experience customer service every day, thus, we understand that quality of customer service and after sales is one of the most enriching comforts of customer value. These are all characteristics of devotion and really everyone is looking for a good product with these attributes.

The first question most people want properly answered is, do LED grow lights work?

But the more important question to ask yourself is, how do I protect myself and avoid being swindled into purchasing a poor quality product that won’t grow anything of good quality or quantity?

Well, as already mentioned, don’t even bother with a product that has no-name or generic components, they simply won’t do well for you. Look for a grow light with a certification you know and trust, such as CSA or UL!

Some people prefer to raise a debate weather LEDs work well or not and some of the debate comes from the earlier days when LED grow lights were in their infancy and far more was claimed for them than was realistically possible. The first attempts of LED grow lights simply couldn’t back the notion of having enough power, and intensity.

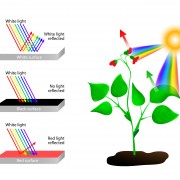

Must we mass-debate? Simply put, plants fundamentally need two things from light: specific wavelengths (spectra) and amplitude (intensity). The reason why people insisted that LED technology entered into competition or contest in their minds in the first place was the realization that they can be fine tuned to specific wavelengths. Grow lights and the industry have come a long way and we are now in a moment where the technology has placed itself in the homes of many. Led lighting is the future path to embrace for new and expert gardeners, amateurs and professionals alike.

It is well known that plants have four distinct chlorophyll receptors, so many manufacturers in the industry quickly adapted the use of 3 (tri-band) and 4 band LEDs addition of deep-red (660–680nm) and royal blue (440–470nm). The 3 and 4 band LED units were still missing a few key colour bands that ignored key minor receptors used to convert energy that are essential for optimal health. Through the evolution of manufacturing 2 (bi-band), 3 (tri-band), and 4 band LED grow lights, much research still revealed that further bands were needed so industry leaders again went back to the drawing board and added even more bands, particularly in the UV and far-red spectra. Even with multi-band lights, yellow (570-590nm) and green (525–570nm) were largely absent, so some engineers added white emitters to fill in the missing colours.

This is partially why the leading manufacturers of LED grow lights are targeting these secondary receptors by adding full spectrum white LEDs to a multi-band mix or switching to white LEDs entirely.

LEDs are monochromatic and coloured solid state lighting sources that emit light in various colour, this all depends on the colour rendering index (CRI). When someone asks, “What about white LEDs?”, the only answer is, “There are no white LED chips as white light is created using multiple colours and this phenomenon is known as metamerism. In colorimetry, metamerism is the matching of apparent colour of objects with different spectral power distributions.

However, white light can be produced by combining the wavelengths of yellow and blue but the spectral density is not that which resembles natural light from that of which we have evolved with when referencing the sun.

Phosphor is the most commonly used method of producing white light with LED grow lights. When describing a general phosphor white manufacturing process, the coating is deposited on the LED die. The exact shade or colour temperature of white light produced by the LED is determined by the dominant wavelength of the blue LED and the composition of the phosphor, itself.

The phosphor material is generally formed by introducing a suspension of phosphor particles onto a carrier (silicone) encapsulating the LEDs in the carrier to provide a solid layer of material in which the phosphor particles will remain suspended.

Phosphors generate heat and many of them are currently temperature sensitive with many of the manufacturing practices. When you combine a phosphor coated LED with a cured silicone carrier in high power applications, the cured silicone may crack and will result in a reduced lifetime of the phosphor coated LED, thus there is a greater cost to replace the component itself as opposed to non-phosphor coated LED applications where costs are minimised in circumstances of breakdown.

The thickness of the phosphor coating produces variations in the colour temperature of the LED. Many manufacturers have attempted to minimise the colour variations by controlling the thickness and composition of the phosphor layers during manufacturing. Some have even tried using multiple layers of coating.

But there are many unpredictable phase relationships with each other over different periods of time. The blue die and the yellow phosphor will degrade and the light that is delivered will result by showing a slow decay in brightness and also a shifting of colour (which will also produce unexpected colours that are ultimately being delivered to your garden), especially if the device is operated at a different current or operating temperature. Therefore, if there is too much stress on your light due to your growing environment, in a viscous cycle your light will stress your plants. This requires a precise and ample amount of environmental monitoring, especially with the physical grade of the LED components. Currently, the phosphorus applications are ideal for a short term but if you want something that lasts with respect to quality and quantity of spectral output, you must look for a company with a great guarantee with respect to these very aspects.

It is true that most land plants can grow to fruition merely on two narrow spectral bands; one with an average central peak at 630-680nm (red) and one 440–470nm (blue). Narrow band devices allow us to precisely control not only the quantity and also spectral quality but two-band LED grow lights do not target all of the chlorophyll receptors. The amount of energy that is put into a lamp and that is actually converted to light is directly what we quantify its efficiency by. In the case of two band LED lamps the production of your crop will have poor results and unsatisfying quality.

Presently, there are companies that will approach you with consistent marketing and tell you that their grow lights are the best and once you buy, seemingly they leave you on your own, giving you very little time and feedback. Do not simply look for a grow light on E-bay or Amazon and think your going to come out on top, happy with your results of your experience in growing. Many of these lights will deliver you poor and unsatisfactory results. If your are considering purchasing grow lights from a company that build only with strictly blue and red (2 band), you may be disappointed with your harvest for both quality and quantity and they’ll likely run rather hot. You may have heard phrases like, “Our grow lights offer you the correct bands or spectrum of light”, when in fact, there is no precisely defined boundary between the bands of the electromagnetic spectrum. They rather fade into each other like the bands of a rainbow.

If you search through the different LED grow lights on the market you will observe that there are different bands advertised as 3, 4, 5, 6, or even 11 and this means they are offering a grow light with spectral gaps. Meaning, there are peaks and troughs in the spectrum which is produced by those lamps rather than one continuous full or broad spectrum. The delivery of light in a continuous (full broad) spectrum by the way of narrow waveband is more balanced and smooth. Of these mentioned 3, 4, 5, 6 and 11 band products, some ‘function’ in a general range but not the entire spectrum has a balance of colour uniformity which is required for a successful, fast and big yielding crop. These are not full spectrum grow lights!

These types of LED grow lights are being sold surreptitiously as ‘better grow lights’ yet the output resembles that of HID in that there are spectral gaps and troughs, which look rigid on a graph and are missing peak absorption levels to a plant.

These companies are marketing their product stating that their grow lights have many ‘more’ bands of light. In some cases these lights are of older technology and are simply marketing tactics, as they’re offering you a grow light that emits bands of light that your plantation ultimately may not use or need for photosynthesis. Hence, they are adding light that is a waste of energy and may merely be a ‘source’ of radiant heat which will then require additional cooling and ultimately costs you more on electricity. With some brands, the higher the watt rating, the less energy efficient the unit becomes because they turn more and more electricity into heat which is wasteful and will need heat management costing you your hard earned dollars on extras to help cool your gardening area.

Presently there are many 1 watt, 3 watt and 5 watt LED lights on the market. 1 watt LEDs are a thing of the past as many of the older 1 watt builds leave you with overheating as they are running at too high of a driving current.

There are also a few companies who carry 5 watt LEDs and they are of good quality, but they also carry a hefty price tag and 5 watt LEDs do not necessarily place 3 watt LEDs out of competition. Not all LEDs are created equal, therefore be careful when purchasing a product that runs its driving current above 80-90%. This is a valuable point for a couple of reasons because the life of your unit will be drastically reduced or may even fail and you will be dismayed due to the fact that you will have to purchase a new unit prior to the given average lifetime due to overheating.

Loss of intensity or loss of colour is also an issue with LED units with high driving current, as it is true that all lighting loses intensity and colour through normal use. When it comes to plant growth, these losses can mean wasted electricity and poor plant performance.

Wattage is an improper comparison between traditional grow lights and LED lights. A much more valuable comparison is the PAR value of the light, which is a measure of the Photosynthetically Active Radiation. 3 watt and even 5 watt LEDs are now the most commonly used in LED grow lights for high PAR rating. LED grow lights are now being produced which exceed 1200 watts and this would be physically possible with 1 watt LEDs but it would not be practical for most applications.

Full Spectrum grow lights carry the blue spectrum which stimulates vegetative growth and the yellows, ambers/orange, reds and far-red spectra which stimulates pre-flowering and flowering (reproductive growth). Virtually all plant life will grow from germination to maturity using grow lights with wavelengths in the ranges of 380 to 730nm that target all four receptors of chlorophyll A and chlorophyll B absorption peaks.

Sensory photoreceptors absorb light in these particular regions of the visible light spectrum because of the quality of light available from the grow lights spectral output. Plants have have individual ‘photoreceptors’ – proteins which absorb light at specific wavelengths.

Why does plant-life grow in the visible spectra? 400nm to 730nm is the peak area for Chlorophyll’s absorption. Below 400nm there is an increase of energy, the photons in this spectra range will increase the risk of photochemical damage if used in excess. But generally speaking, beyond 700nm the energy levels are insufficient to effectively drive photochemistry for vegetative growth and pre-flowering. Far-red light resides around (700-800 nm) and is critical for the germination and flowering of many plants, but not all types.

When referring to the sun, the light that it emits for UV is in the range of (280 – 400 nm), yet there are different UV levels including UVA 315–400nm, UVB 280–315nm or UVC 290-100nm. An approximate accumulation of UV from the sun is 4%. As mentioned above, certain plant families require specific spectra for their developmental stages.

[/su_spoiler]

Please also see: Resin, Herbs & Beauty Care From Your Garden.