LED vs HID vs CFL’s

/0 Comments/in Light Life /by hyperweb1LED vs HID vs CFLs

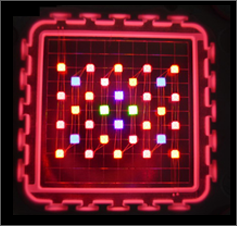

COB-Circuit on Board Chip set

LEDs are considered heavy-duty, they have no electrode or filament, and they are shock & vibration resistant. LEDs turn on instantly, the do not flicker and they create focused light. LEDs are a higher upfront cost but as compare to that of their predecessor there are virtually no maintenance expenses.

Unlike incandescent bulbs, which use a filament, or compact florescent lamps (CFLs), which rely on gas, LED’s create light by exciting electrons. Inside each LED is a semiconductor material consisting of positively and negatively charged parts. When the light is turned on and an electricity strikes the semiconductor, electrons become charged and begin to flow from a negative to a positive layer within the semiconductor. As the excited electrons pass through holes in the material, they emit photons of light and cause the LED to illuminate.

Most CFL bulbs emit a wavelength with spikes in both blue and red light spectra, which combined make up the white light that you see. The further from the plant that you have the CFL bulb, the less usable energy is absorbed by the plant, hence decreasing their efficiency Most CFL bulbs do not emit significant volumes of heat allowing you to have your plant in close proximity to the bulb to maximize efficiency.

CFL

If you are still in the dark over which energy-efficient alternative to use, I will highlight what is in store for your near future.

LED lights last longer, so even though you’re paying more at purchase time, you are spending less over the long period and as well you are saving yourself valuable time in transactions of having to repurchase more bulbs and ballasts for replacements like with CFLs, HIDs, HPS and MH. LED’s last longer and do not breakdown or have the same maintenance regime as CFLs for their life-cycle.

LED lights generally cost more to buy than CFLs, but manufacturing technologies are lowering these prices continually, and when you consider the lifespan differences, LED’s by far outlast.

To get the filament to glow white, it needs to be very hot so that most of the electric energy is used to make heat, not produce light. In fact incandescent bulbs are only about 6% efficient. CFLs work the same way as a fluorescent light works. The bulb is filled with a gas that gives off UV rays when excited by an electric signal. The UV rays then hit a phosphor coating on the inside of the bulbs causing it to glow and give off light.

The primary disadvantage to CFL lights is the mercury contained in the bulb. This is ordinarily not a problem, but if the bulb breaks clean up is a hassle. Mercury is a dangerous heavy metal, and proper clean up and disposal of CFL bulbs is critical. Never put a used CFL bulb in with the rest of your trash.

LED’s are 70-90% more efficient and do not contain dangerous bi-products therefore they also provide a safer working or home environment. Besides your own health and safety, have you ever considered the safety of the produce you are trying to growing in an organic way?

HID bulbs are considered fragile they have moving parts, glass bulbs, and filaments. They required 5-10 minute warm-up time and disburses light in all direction. When you take a closer look at the difference between the two and make comparisons HID bulbs are a waste in more ways than one way. HID have lower upfront cost, but require regular replacements of bulbs and ballast and, when you add up the cost difference with these frequent replacements it only makes sense to consider using LEDs.

Serious horticulturalists that use HPS recommend that you replace your lamps after 6000 hours of use. This equates to using your light 16 hours a day for one year. Have you ever done the math on the replacement bulbs? The time and effort associated to cleaning and changing bulbs alone are costly, let alone the replacement of ballasts on-top. Most lamp manufacturers rate their lamps by “Average Life Hours” and usually claim 10,000 to 24,000 hours. These ratings are based on when the lamp will completely fail to come on. They do not factor in loss of intensity or loss of colour. HID lamps lose intensity and colour through normal use. When it comes to plant growth, these losses can mean wasted electricity and poor plant performance.

HPS are a class of gas-discharge arc lamps that form light by transmitting an electrical current between two electrodes and an ionized gas. The light radiates from the arc when charged electrons change orbit as they interact with the gas. All is hermetically sealed inside a quartz glass capsule. Generally, an extra gas is also used, which helps to distinguish the main types of HID: High Pressure Sodium, Metal Halide, Low Pressure Sodium, Mercury Vapor. Every HID requires a ballast to regulate its power and to create the initial surge of electricity that allows the light to start. Of course when it all come down to it there is more to a grow light than just the bulb. You will have to purchase the reflector, cord, ballast, bulb and other parts separately, or buy a whole system that just needs to be plugged in. But when it all comes down to it LED grow lights outrank these outdated methodologies of using bulbs ad there lifespan is 50000 hours and there are no extras that you have to purchase, just plug-in and grow.

High Pressure Sodium (HPS) Bulbs produce a red-orange light that benefits flowering. With an average lifespan 2X that of metal halides, high pressure sodium lamps aren’t economical, when compared to LED grow lights. This isn’t a great light if you are only going to use one, as it doesn’t produce light in the blue spectrum needed for leafy growth.

Metal Halide (MH) Bulbs produce a blue-white color that is conducive to encouraging leafy growth and keeps plants compact. A bulb will last about 10,000 hours and produce up to 125 lumens per watt compared to 39 lumens per watt for standard fluorescent lights and 18 lumens per watt for standard incandescent bulbs. Gardeners who use this archaic technology would start plants out with. When it comes time to flower, switch to a High Pressure Sodium bulb.

The broad spectrum LED grow lights are designed to be run at higher-wattage which create a higher concentration of light (PAR) from a single focal point, allowing the specific spectral range of light to travel further and also creating a larger canopy thus a bigger garden. These wavelengths are the ultimate necessity, as they supply the energy used for photosynthesis by Chlorophyll A and Chlorophyll B during both the vegetative and bloom stages.

The broad spectrum lights are designed with a specific ratio for Primary lighting or sole-source lighting systems for crop production as they utilise multiple wavelengths specific for photosynthesis. The COB series LED Grow lights can be customised to fit your gardening needs, whether you need more Blue or Red, IR or UV we can supply you with a different ratio throughout most of our models. Ultraviolet light is predominantly nonexistent in indoor gardens that use only HID bulbs. Many gardeners are enhancing essential-oil production and promoting stronger structural integrity in their plants with the use of UV emitting LEDs.

Some LED manufacturers will work with you to develop a specific spectral strategy to sequence or create a ‘Recipe of Light’. This approach is advantageous for your operation because it leads toward your goals and innovations through customisation of the lamps according to the spectrum you may need for what you are growing. For instance, you may have a fruit bearing plant or tree and so you may choose to have supplementary lighting to suit the plants individual needs. Blue for vegetation and red & orange for fruiting and of most spectral developers provide solutions with IR and UV as well, but this all depends on your methodologies and what you are growing.

LED grow lights are very different in contrast to HPS-High Pressure Sodium/MH-Metal Halide horticultural lighting technologies and because they are of a newer revolution in technology but you don’t have to limit yourself or shy yourself away from LEDs because you are not accustomed to using them in the same fashion to grow from seed to harvest with them. Much of your accumulated knowledge from past growing will definitely be of benefit with your decision to switch to LEDs. In the past High Pressure Sodium and Metal Halide bulbs were the only ones indoor gardeners will say they needed but they are older technologies and as such they are dangerous and pose threats to your health due to the fact that they contain dangerous (toxic) gases that are heated to very high temperatures. When working with these types of bulbs slight error such as touching the bulb with your finger can transfer oils to the glass. The oils could heat up faster than the actual bulbs and you are left with a potential explosion or fire.

HPS-Potential Fire Risk

HPS/MH bulbs contain heavy metal(s) which also pose a threat to you household and your health. When using LEDs these environmental concerns are not an issue, in fact many people have made the switch because they have are assured that their garden does not have the same potential fire dangers either, as LED lighting operate at a very low temperature as opposed to HPS environments. This is very assuring as you can use a simple timer and leave your garden for a couple of days an not worry about the potential hazards.

High quality LED grow lights are known for the longevity of their lifespan and run upwards of 50000 hours. Plants do not need as many ‘light hours’ while using LED’s as the spectral output is specifically designed to mimic that of the sun. When comparing LEDs to the archaic HPS-High Pressure Sodium/MH-Metal Halide technologies, LED grow lights do not decline in spectral output at a fast rate so they by far outshine and last in comparison.

Light-emitting diodes (LEDs) have a variety of advantages over traditional forms of horticultural lighting. Their small size, durability, long lifetime, cool emitting temperature, and the option to select specific wavelengths for a targeted plant response make LEDs more suitable for plant-based uses than many other light sources. Unlike other light sources the spectrum of LEDs can be customised to meet the needs of specific plant families because certain plant families require different qualities of light for anatomy, morphology, nutrient uptake and pathogen development.

LED grow lights do not require a ballast, therefore you can plug your light directly into a wall outlet. Thus there is direct savings because there is no need to replace bulbs, and such savings can be reallocated into your home and families groceries associated to urban indoor gardening. In fact, some LED grow lights are adequate in the sense that they are 90% more cost efficient and 100% more spectral efficient.

When comparing the cost efficiency with regards to the replacement of HID/HPS/MH bulbs a vs Led lighting one begins to realize that LEDs are the new high tech revolution for indoor gardening and green housing. 50000 hours of output would roughly equate to 5 bulb changes, if not more and when adding up the cost and time associated to these changes LEDs are the solution.

LED grow lights are advancing in the marketplace and are the number one, clean tech choice by many consumers who are rapidly replacing their their High intensity Discharge (HID) bulbs such as High Pressure Sodium (HPS) and Metal Halide (MH) bulbs.

Leave a Reply

Want to join the discussion?Feel free to contribute!